Electric Car Batteries and Characteristics

Electric Car Batteries

Electric car batteries are one of the most important components in a car system. In BEV cars, batteries are the only “life”. Because, only electrical energy stored in the battery is the only source of energy driving the BEV car. There are no other sources. The types of electric car batteries are also depends on the car system. The most popular electric car battery used is lithium-ion. Batteries that are considered zero emission abbreviated as ZEBRA. The most suitable battery for hybrid electric cars is NiMH. This article will explain at a glance about the different types of electric vehicle batteries and their characteristics along with a little about the Battery Management System (BMS)of an electric car.

Types of Electric Car Batteries

Electric car batteries are different from SLI batteries (starting, lightning and ignition). SLI batteries are batteries that are usually installed in gasoline or diesel cars. This type of electric cars battery is designed as an energy storage system, capable of delivering power for long and sustainable periods.

There are 5 types of electric vehicle batteries to be discussed in this article:

- Lithium-Ion (Li-On)

- Nickel-Metal Hybrid (NiMH)

- Lead Acid (SLA)

- Ultracapacitor

- ZEBRA (Zero Emissions Batteries Research Activity)

The comparison of the first four types of electric car batteries can be seen as follows:

———————————————

Lithium-Ion Battery (Li-On)

This type of electric vehicle battery is most widely applied is the Li-On battery. This battery may already be familiar to us because it is also used in many portable electronic equipment such as cellphones and laptops. The main difference is a matter of scale. Its physical capacity and size on electric cars is much greater – this is often referred to as a traction battery pack.

This type of electric vehicle battery is most widely applied is the Li-On battery. This battery may already be familiar to us because it is also used in many portable electronic equipment such as cellphones and laptops. The main difference is a matter of scale. Its physical capacity and size on electric cars is much greater – this is often referred to as a traction battery pack.

Li-on batteries have a very high power to weight ratio. This type of electric car battery is high energy efficiency. Performance at high temperatures is also good. The battery has a greater energy ratio per weight – a parameter that is very important for electric car batteries. The smaller the battery weight (same kWH capacity) means the car can travel further with a single charge.

This battery also has a low “self-discharge” level, so the battery is better than any other battery in maintaining its ability to hold its full charge.

In addition, most parts of Li-on batteries can be recycled, making it the right choice for those interested in environmentally conscious electric cars. BEV cars and PHEVs use the most lithium batteries.

Li-on battery Types

- Lithium Iron Phosphate(LiFePO4) — LFP

- Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2) — NCA

- Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2) — NMC

- Lithium Titanate (Li2TiO3) — LTO

- Lithium Manganese Oxide (LiMn2O4) — LMO

- Lithium Cobalt Oxide(LiCoO2) — LCO

Li-ion battery parameters

———————————————

Hybrid Nickel-Metal (NiMH) Batteries

NiMH batteries are more widely used by hybrid-electric vehicles (HEV), but are also used successfully in some BEV cars. This type of hybrid electric car battery does not get power from outside (can be recharged from an outside source of the car system). The recharging of hybrid electric car batteries depends on engine speed, wheels and regenerative braking.

NiMH batteries are more widely used by hybrid-electric vehicles (HEV), but are also used successfully in some BEV cars. This type of hybrid electric car battery does not get power from outside (can be recharged from an outside source of the car system). The recharging of hybrid electric car batteries depends on engine speed, wheels and regenerative braking.

NiMH batteries have a longer life cycle than lithium-ion batteries or SLA batteries. NiMH batteries are safe and tolerant of incorrect usage. The biggest disadvantages of NiMH batteries include:

- The price is relatively more expensive

- High self-discharge rate

- Generate significant heat at high temperatures.

These deficiencies make NiMH less effective as a battery for electric cars whose batteries must be able to be recharged from outside the system, such as from the PLN network. That is why the car battery is the most widely applied by hybrid cars.

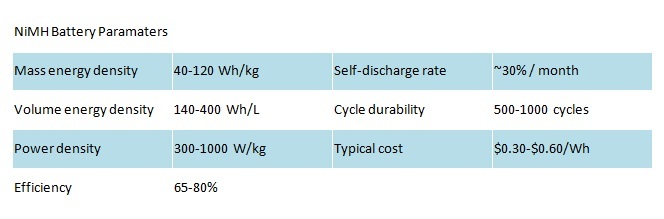

NiMH battery parameters

———————————————

Lead-Acid (SLA) Batteries

SLA (lead-acid) batteries are the oldest rechargeable batteries. Compared to lithium and NiMH batteries, lead-acid batteries do lose capacity and are much heavier, but the price is relatively cheap and safe. There are large capacity SLA electric car batteries under development, but SLA batteries are now only used by commercial vehicles as a secondary storage system.

Lead-acid battery parameters

———————————————

Ultra-capacitor Batteries

The ultra-capacitor battery is not like the general definition of a battery. In contrast to other electro-chemical batteries, this type of electric vehicle battery actually stores polarized liquid between the electrode and the electrolyte. As the surface area of the liquid increases, the energy storage capacity also increases. Like SLA batteries, ultra-capacitor batteries are very suitable as secondary storage devices in electric vehicles. This is because the ultra-capacitor helps electro-chemical batteries increase their load levels. In addition, ultra-capacitor can provide extra power to electric vehicles during acceleration and regenerative braking.

The ultra-capacitor battery is not like the general definition of a battery. In contrast to other electro-chemical batteries, this type of electric vehicle battery actually stores polarized liquid between the electrode and the electrolyte. As the surface area of the liquid increases, the energy storage capacity also increases. Like SLA batteries, ultra-capacitor batteries are very suitable as secondary storage devices in electric vehicles. This is because the ultra-capacitor helps electro-chemical batteries increase their load levels. In addition, ultra-capacitor can provide extra power to electric vehicles during acceleration and regenerative braking.

———————————————

ZEBRA Batteries

The battery for ZEBRA electric cars is a low-temperature variant of sodium-sulfur (NaS) batteries and is a development of ZEBRA (originally “Zeolite Battery Research Africa” then became a “Zero Emissions Batteries Research Activity” battery) in 1985. From the beginning ZEBRA batteries were indeed developed for electric vehicle applications. The battery uses NaAlCl4 with Na + -beta-alumina ceramic electrolyte.

The battery for ZEBRA electric cars is a low-temperature variant of sodium-sulfur (NaS) batteries and is a development of ZEBRA (originally “Zeolite Battery Research Africa” then became a “Zero Emissions Batteries Research Activity” battery) in 1985. From the beginning ZEBRA batteries were indeed developed for electric vehicle applications. The battery uses NaAlCl4 with Na + -beta-alumina ceramic electrolyte.

Characteristics of ZEBRA batteries

- High power cell so that it fits as an electric car battery

- High temperature batteries operate at more than 270 ° C

- The chemical Sodium Nickel Chloride (NaNiCl) provides a nominal operating cell voltage of 2.58 Volts

Advantages of ZEBRA battery

- High energy density (5 times higher than SLA batteries)

- Large cells (up to 500Ah) allow

- Life cycle> 1000 cycles

- Short circuit tolerance

- Safer than Sodium Sulfur cells

- The typical cell failure is shorted but does not cause the battery to fully damage.

- Low cost ingredients

Disadvantages of ZEBRA battery

- Suitable for large capacity batteries (> 20KWh)

- Limited size and capacity range

- Only one factory in the world produces this battery.

- High internal resistance

- Liquid sodium electrode

- High operating temperature.

- Preheating is required to get the battery up to an operating temperature of 270 ° C (up to 24 hours from cold conditions)

- Uses 14% of its own capacity per day to maintain temperature when not in use.

- Thermal management is required

———————————————

Battery Management System

Battery management system or Battery Management systems (BMS) is a technology system that functions to maximize the life of electric vehicle battery and its characteristics. It is strongly recommended that all battery powered electric vehicles be installed BMS. The aim is to ensure the battery stays within the ideal working parameters. Some battery chemicals (such as lead acid) are quite tolerant of misuse, but lithium and NiMH can both be permanently damaged by a misuse such as over charging, over discharging, or overheating. All types of electric car batteries will benefit greatly by installing a BMS.

Some special functions of the battery management system include:

- Charge balancing, to ensure all cells complete charging at the same time then to prevent damage through overcharging.

- Active balancing, in which energy is transferred from stronger cells to weaker cells, to ensure all cells reach the maximum discharge point at the same time.

- Temperature monitoring (temperature monitoring), to avoid damage due to overheating.

- Low-voltage cut-off, a way to isolate a battery when any cell reaches the recommended minimum voltage, and to avoid damage due to overuse.

- State of charge (SOC) monitoring of all battery cells for electric cars. Through monitoring voltage and current, the remaining capacity of each cell can be calculated.

Comments

Post a Comment